HYTORC螺母

紧固件

对于需要最高水平螺栓负载控制的关键应用,获得专利的HYTORCluo'wu系统可提供业界领先的接头完整性。这种三件式紧固件对螺栓施加纯粹的张力,以防止螺纹损坏并确保螺栓负载精度。有多种材料可供选择,适用于从极端温度到恶劣气候的所有应用。

螺栓张紧器 - 校准负载精度

没有其他螺栓系统提供相同水平的可重复精度,确保均匀的螺栓负载,以消除关节故障和无意的螺母松动。工具寿命

其它螺栓连接系统将反作用臂和方形驱动装置放在工具的相对两侧,从而在工具主体中产生高应力,随着时间的推移可能会导致故障。HYTORC螺母将作用力和反作用力置于方形驱动轴上,以消除大部分内应力,并延长工具的使用寿命。防磨损移除

HYTORC螺母是唯一可以保证在安装和拆卸时消除带螺纹或损坏螺纹的紧固件。这些紧固件已经安装在各种高温应用中十年或更长时间,并且在不损坏螺栓的情况下被拆除,从而无需更换螺栓,从而大大节省了成本。文档

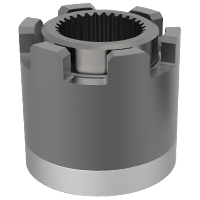

TN SERIES

TN SERIES GT SERIES

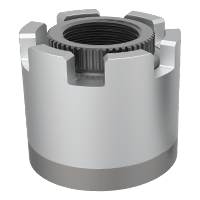

GT SERIES CT SERIES

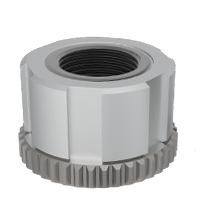

CT SERIES SN SERIES

SN SERIESTURBINE STYLE LIMITED RADIUS NUT

Our most popular Nut! Designed to overcome the tight radial restrictions and high temperatures in steam turbine engines. When a bolted connection has a challenging counter bore or flanged radius, the TN-Series Nut will solve the problem.CHEMICAL STYLE LIMITED RADIUS NUT

The CT Nut’s thicker outer sleeve minimizes stress and allows it to handle high loads at elevated temperatures. The through-bolt design makes them ideal for applications with high stud protrusions from the flange.LOW CLEARENCE STYLE NUT

The low-profile SN Series is the ideal choice for tight overhead restrictions where traditional fasteners can’t fit. The through-bolt design is useful for situations where high stud extensions make standard nuts impractical.GAS TURBINE STYLE NUT

Originally specified for Gas Turbine applications to handle elevated temperatures, high stress and greater load to breakout factors. For oversized applications where higher loads and breakout torques are needed.Imperial

Metric

TN Series (Inch)

| Blank Size | Size Code | Nominal Stud Size | OD | H | Max Stroke |

| 01 | 014 | 7/8 | 1.400 | 1.313 | 0.197 |

| 02 | 100 | 1 | 1.600 | 1.500 | 0.225 |

| 03 | 102 | 1-1/8 | 1.800 | 1.688 | 0.254 |

| 04 | 104 | 1-1/4 | 2.000 | 1.875 | 0.281 |

| 05 | 106 | 1-3/8 | 2.200 | 2.063 | 0.310 |

| 06 | 108 | 1-1/2 | 2.400 | 2.250 | 0.338 |

| 07 | 110 | 1-5/8 | 2.600 | 2.438 | 0.366 |

| 08 | 112 | 1-3/4 | 2.800 | 2.625 | 0.394 |

| 09 | 114 | 1-7/8 | 3.000 | 2.813 | 0.422 |

| 10 | 200 | 2 | 3.200 | 3.000 | 0.450 |

| 11 | 204 | 2-1/4 | 3.600 | 3.375 | 0.506 |

| 12 | 208 | 2-1/2 | 4.000 | 3.750 | 0.563 |

| 13 | 212 | 2-3/4 | 4.400 | 4.125 | 0.619 |

| 14 | - | - | 4.535 | 4.253 | 0.638 |

| 15 | 300 | 3 | 4.800 | 4.500 | 0.675 |

| 16 | - | - | 5.040 | 7.725 | 0.709 |

| 17 | 304 | 3-14 | 5.200 | 4.875 | 0.731 |

| 18 | 308 | 3-1/2 | 5.600 | 5.250 | 0.788 |

| 19 | 312 | 3-3/4 | 6.000 | 5.625 | 0.844 |

| 20 | 400 | 4 | 6.400 | 6.000 | 0.900 |

| 21 | 404 | 4-1/4 | 6.800 | 6.375 | 0.956 |

| 22 | 408 | 4-1/2 | 7.200 | 6.750 | 1.013 |

| 23 | 412 | 4-3/4 | 7.600 | 7.125 | 1.069 |

| 24 | 500 | 5 | 8.000 | 7.500 | 1.125 |

| 25 | 504 | 5-1/4 | 8.400 | 7.875 | 1.181 |

| 26 | 508 | 5-1/2 | 8.800 | 8.250 | 1.238 |

TN Series (mm)

| Blank Size | Size Code | Nominal Stud Size | OD | H | Max Stroke |

| 01 | 022 | M20 | 35.56 | 33.35 | 5.00 |

| 02 | 024 | M24 | 40.64 | 38.10 | 5.72 |

| 03 | 027 | M27 | 45.72 | 42.88 | 6.45 |

| 04 | 030 | M30 | 50.80 | 47.63 | 7.14 |

| 05 | 033 | M33 | 55.88 | 52.40 | 7.87 |

| 06 | 036 | M36/M39 | 60.96 | 60.96 | 8.59 |

| 07 | 039 | M42* | 66.04 | 61.93 | 9.30 |

| 08 | 042 | M45 | 71.12 | 66.68 | 10.01 |

| 09 | 045 | M48 | 76.20 | 71.45 | 10.72 |

| 10 | 048 | M52 | 81.28 | 76.20 | 11.43 |

| 11 | 052 | M56 | 91.44 | 85.73 | 12.85 |

| 12 | 056 | M64 | 101.60 | 95.25 | 14.30 |

| 13 | 064 | M70 | 111.76 | 104.78 | 15.72 |

| 14 | 070 | M72 | 115.19 | 108.03 | 16.21 |

| 15 | 072 | M76 | 121.92 | 114.30 | 18.01 |

| 16 | 076 | M80 | 128.02 | 120.02 | 18.01 |

| 17 | 080 | - | 132.08 | 123.83 | 18.57 |

| 18 | - | M90 | 142.24 | 133.35 | 20.02 |

| 19 | 090 | M95 | 152.40 | 142.88 | 21.44 |

| 20 | 095 | M100 | 162.56 | 152.40 | 22.86 |

| 21 | 100 | M110 | 172.72 | 161.93 | 24.28 |

| 22 | 110 | M115 | 182.88 | 171.45 | 25.73 |

| 23 | 115 | M120 | 193.04 | 180.98 | 27.15 |

| 24 | 120 | M125 | 203.20 | 190.50 | 28.58 |

| 25 | 125 | M130 | 213.36 | 200.03 | 30.00 |

| 26 | 130 | M140 | 223.52 | 209.55 | 31.45 |

CT Series (Inch)

| Blank Size | Size Code | Nominal Stud Size | OD | H | Max Stroke |

| 01 | 014 | 7/8 | 1.660 | 1.429 | 0.201 |

| 02 | 100 | 1 | 1.811 | 1.559 | 0.220 |

| 03 | 102 | 1-1/8 | 2.038 | 1.754 | 0.247 |

| 04 | 104 | 1-1/4 | 2.264 | 1.949 | 0.275 |

| 05 | 106 | 1-3/8 | 2.491 | 2.144 | 0.302 |

| 06 | - | - | 2.717 | 2.339 | 0.330 |

| 07 | 108 | 1-1/2 | 2.943 | 2.533 | 0.357 |

| 08 | 110 | 1-5/8 | 3.170 | 2.728 | 0.384 |

| 09 | 112 | 1-3/4 | 3.396 | 2.923 | 0.412 |

| 10 | 114 | 1-7/8 | 3.623 | 3.118 | 0.439 |

| 11 | 200 | 2 | 3.925 | 3.378 | 0.476 |

| 12 | 204 | 2-1/4 | 4.226 | 3.638 | 0.513 |

| 13 | 208 | 2-1/2 | 4.830 | 3.914 | 0.586 |

| 14 | 212 | 2-3/4 | 5.283 | 4.547 | 0.614 |

| 15 | - | - | 5.434 | 4.677 | 0.659 |

| 16 | 300 | 3 | 5.736 | 4.937 | 0.696 |

| 17 | - | - | 6.038 | 5.197 | 0.732 |

| 18 | 304 | 3-1/4 | 6.340 | 5.457 | 0.769 |

| 19 | 308 | 3-1/2 | 6.793 | 5.846 | 0.824 |

CT Series (mm)

| Blank Size | Size Code | Nominal Stud Size | OD | H | Max Stroke |

| 01 | 022 | M22 | 42.16 | 36.30 | 5.11 |

| 02 | 024 | M24 | 46.00 | 39.30 | 5.59 |

| 03 | 027 | M27 | 51.77 | 44.55 | 6.27 |

| 04 | 030 | M30 | 57.51 | 49.50 | 6.99 |

| 05 | 033 | M33 | 63.27 | 54.46 | 7.67 |

| 06 | 036 | M36 | 69.01 | 59.41 | 8.38 |

| 07 | 039 | M39 | 74.75 | 64.34 | 9.07 |

| 08 | 042 | M42 | 80.52 | 69.29 | 9.75 |

| 09 | 045 | M45 | 86.26 | 74.24 | 10.46 |

| 10 | 048 | M48 | 92.02 | 79.20 | 11.15 |

| 11 | 052 | M52 | 99.70 | 85.80 | 12.09 |

| 12 | 056 | M56 | 107.34 | 92.41 | 13.03 |

| 13 | 064 | M64 | 122.68 | 99.42 | 14.88 |

| 14 | 070 | M70 | 134.19 | 115.49 | 15.60 |

| 15 | 072 | M72 | 138.02 | 118.80 | 16.74 |

| 16 | 076 | M76 | 145.69 | 125.40 | 17.68 |

| 17 | 080 | M80 | 153.37 | 132.00 | 18.59 |

| 18 | - | - | 161.04 | 138.61 | 19.53 |

| 19 | 090 | M90 | 172.54 | 148.49 | 20.93 |

SN Series (Inch)

| Blank Size | Size Code | Nominal Stud Size | OD | H | Max Stroke |

| 01 | 014 | 5/8-7/8 | 1.880 | 1.210 | - |

| 02 | 100 | 1 | 2.050 | 1.210 | 0.225 |

| 03 | 102 | 1-1/8 | 2.313 | 1.360 | 0.249 |

| 04 | 104 | 1-1/4 | 2.500 | 1.518 | 0.281 |

| 05 | 106 | 1-3/8 | 2.688 | 1.670 | 0.310 |

| 06 | 108 | 1-1/2 | 2.938 | 1.821 | 0.338 |

| 07 | 110 | 1-5/8 | 3.250 | 1.974 | 0.366 |

| 08 | 112 | 1-3/4 | 3.417 | 2.125 | 0.394 |

| 09 | 114 | 1-7/8 | 3.667 | 2.277 | 0.422 |

| 10 | 200 | 2 | 3.900 | 2.429 | 0.450 |

| 11 | 204 | 2-1/4 | 4.300 | 2.732 | 0.506 |

| 12 | 208 | 2-1/2 | 4.800 | 3.035 | 0.563 |

| 13 | 212 | 2-3/4 | 5.250 | 3.338 | 0.619 |

| 14 | - | 2-7/8 | 5.375 | 3.440 | 0.638 |

| 15 | 300 | 3 | 5.750 | 3.643 | 0.675 |

| 16 | - | - | 5.750 | 3.824 | 0.709 |

| 17 | 304 | 3-1/4 | 6.083 | 3.945 | 0.731 |

| 18 | 308 | 3-1/2 | 6.667 | 4.250 | 0.788 |

| 19 | 312 | 3-3/4 | 7.000 | 4.550 | 0.844 |

| 20 | 400 | 4 | 7.300 | 4.857 | 0.900 |

| 21 | 404 | 4-1/4 | 7.750 | 5.159 | 0.956 |

| 22 | 408 | 4-1/2 | 8.200 | 5.463 | 1.013 |

| 23 | 412 | 4-3/4 | 8.700 | 5.930 | 1.069 |

SN Series (mm)

| Blank Size | Size Code | Nominal Stud Size | OD | H | Max Stroke |

| 01 | 014 | M20 | 52.07 | 30.73 | - |

| 02 | 024 | M24 | 52.07 | 30.73 | 5.71 |

| 03 | 027 | M27 | 58.67 | 34.54 | 6.47 |

| 04 | 030 | M30 | 63.50 | 38.56 | 7.23 |

| 05 | 033 | M33 | 68.33 | 42.42 | 7.81 |

| 06 | 036 | M36/39 | 74.68 | 46.25 | 8.57 |

| 07 | 042 | M42 | 82.55 | 50.14 | 9.33 |

| 08 | 045 | M45 | 86.87 | 53.98 | 10.09 |

| 09 | 048 | M48 | 93.22 | 57.91 | 10.66 |

| 10 | 052 | M52 | 99.06 | 61.72 | 11.43 |

| 11 | 056 | M56 | 109.22 | 69.34 | 12.95 |

| 12 | 064 | M64 | 121.92 | 77.22 | 14.28 |

| 13 | 070 | M70 | 133.35 | 84.84 | 15.81 |

| 14 | 072 | M72 | 136.65 | 87.38 | 16.19 |

| 15 | 076 | M76 | 146.05 | 92.53 | 17.14 |

| 16 | 080 | M80 | 146.05 | 97.03 | 18.09 |

| 17 | - | - | 154.43 | 100.33 | 18.66 |

| 18 | 090 | M90 | 169.42 | 107.95 | 20.95 |

| 19 | 095 | M95 | 177.80 | 115.57 | 21.52 |

| 20 | 100 | M100 | 185.42 | 123.44 | 22.86 |

| 21 | 110 | M110 | 196.85 | 131.06 | 24.38 |

| 22 | 115 | M115 | 208.28 | 138.76 | 25.71 |

| 23 | 120 | M120 | 220.98 | 150.62 | 27.24 |

GT Series (Inch)

| Blank Size | Size Code | Nominal Stud Size | OD | H | Max Stroke |

| 02 | 100 | 1 | 1.850 | 1.648 | 0.205 |

| 03 | 102 | 1-1/8 | 2.081 | 1.823 | 0.263 |

| 04 | 104 | 1-1/4 | 2.313 | 2.146 | 0.281 |

| 05 | 106 | 1-3/8 | 2.544 | 2.334 | 0.338 |

| 06 | 108 | 1-1/2 | 2.775 | 2.487 | 0.338 |

| 07 | 110 | 1-5/8 | 3.006 | 2.656 | 0.352 |

| 08 | 112 | 1-3/4 | 3.238 | 2.750 | 0.394 |

| 09 | 114 | 1-7/8 | 3.469 | 3.094 | 0.422 |

| 10 | 200 | 2 | 3.700 | 3.145 | 0.450 |

| 11 | 204 | 2-1/4 | 4.163 | 3.540 | 0.506 |

| 12 | 208 | 2-1/2 | 4.625 | 4.073 | 0.574 |

| 13 | 212 | 2-3/4 | 5.088 | 4.349 | 0.680 |

| 14 | 214 | 2-7/8 | 5.244 | 4.477 | 0.698 |

| 15 | 300 | 3 | 5.550 | 4.787 | 0.675 |

GT Series (mm)

| Blank Size | Size Code | Nominal Stud Size | OD | H | Max Stroke |

| 02 | 024 | M24 | 46.99 | 41.85 | 6.34 |

| 03 | 027 | M27 | 52.86 | 46.30 | 6.67 |

| 04 | 030 | M30 | 58.75 | 54.51 | 7.14 |

| 05 | 033 | M33 | 64.62 | 59.28 | 8.57 |

| 06 | 036 | M36/M39 | 70.49 | 63.17 | 8.57 |

| 07 | 042 | M42* | 76.35 | 67.46 | 8.93 |

| 08 | 045 | M45 | 82.25 | 69.85 | 10.00 |

| 09 | 048 | M48 | 88.11 | 78.59 | 10.72 |

| 10 | 052 | M52 | 93.98 | 79.88 | 11.43 |

| 11 | 056 | M56 | 105.74 | 89.92 | 12.85 |

| 12 | 064 | M64 | 117.48 | 103.45 | 14.57 |

| 13 | 070 | M70 | 129.24 | 110.46 | 17.26 |

| 14 | 072 | M72 | 133.20 | 113.72 | 17.74 |

| 15 | 076 | M76 | 140.97 | 121.59 | 17.15 |

简体中文(中国)

简体中文(中国)  English (India)

English (India)  Deutsch (Deutschland)

Deutsch (Deutschland)  Español (España)

Español (España)  English (South Africa)

English (South Africa)  English (Singapore)

English (Singapore)  Français (France)

Français (France)  English (Australia)

English (Australia)  English (United States)

English (United States)  English (United Kingdom)

English (United Kingdom)